Morel Industries Completes Acquisition Plan of Ballard Brass

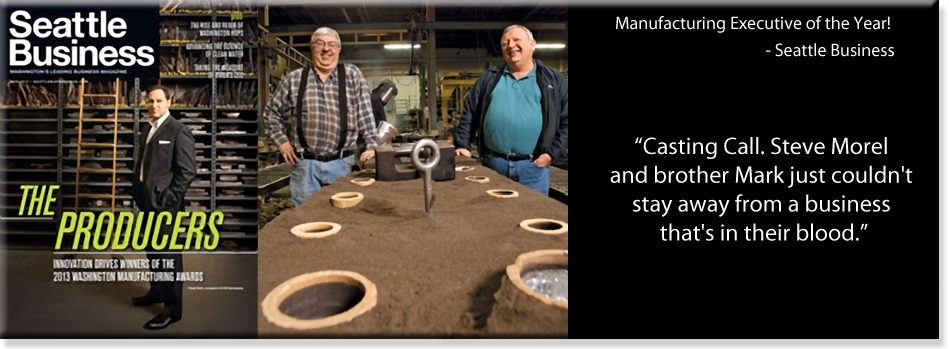

Morel Industries announced today that it has completed its acquisition plan and has moved all Ballard Brass assets to Morel Industries and will no longer operate the brand under Ballard Brass. Morel Industries purchased Ballard Brass back in October of 2000. In 2006, they moved Ballard Brass to their new state-of-the-art 42,0000 sqft. facility in Georgetown. However, Morel Industries continued some branding under the Ballard Brass name and as of today, this will end and Morel Industries will solely brand under their company name.

Mark Morel explains, "When we purchased Ballard Brass we wanted to leverage their well-established name and reduce customer confusion. We feel we have now fully established the Morel Industry brand and our customers solely refer to us a "Morel Industries" and not Ballard Brass, so the time has come".

As part of this final step, www.BallardBrass.com has been removed and their new site, www.MorelIndustries.com will take its place.

Morel Industries Continues to be a Leader in State-Of-The-Art Foundry Technologies

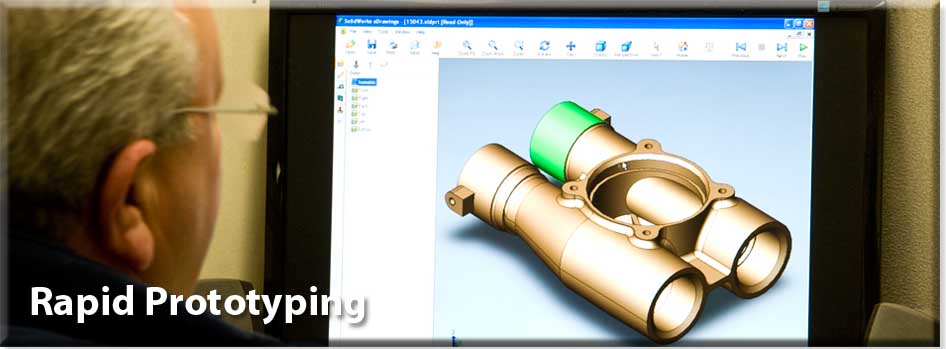

Seattle, Washington – Morel Industries, a global leader of metal casting foundries, has continued to seek the latest in technology to improve its products and processes. Today the company announced their latest technological acquisition through the purchase of a ROMERTM portable arm coordinate measuring machines (PCMM). These state-of-the-art measuring devices are the next generation for precision manufacturing and inspection.

Seattle, Washington – Morel Industries, a global leader of metal casting foundries, has continued to seek the latest in technology to improve its products and processes. Today the company announced their latest technological acquisition through the purchase of a ROMERTM portable arm coordinate measuring machines (PCMM). These state-of-the-art measuring devices are the next generation for precision manufacturing and inspection.

Mark Morel, of Morel Industries explains, “The ROMERTM Arm does two things for us; it allows us to reduce our prototyping time while increasing our pre-production accuracy, and it also allows us to more accurately measure our post-production accuracy which insures our continued production of the World’s most precise foundry and metal casting products”. There is no doubt this technology raises the bar for the industry and puts the Seattle Foundry as a leader in technological advancement.

As the manufacturing world innovates, precision has become increasingly more stringent requirement. Precision manufacturing is required for robotic assembly lines where parts must be accurate within sometimes 1/10000th of an inch. In addition precision casting reduces waste of resources. “When competing globally, especially with China, we must reduce waste as much as possible, while never compromising the integrity of our alloys. The ROMERTM Arm, will help us be more efficient, which in turn helps us be more competitive for our customers.”, says Morel. According to the ROMER website, this technology will give “The ability to quickly measure parts wherever and whenever required allows manufacturers to ensure quality, control processes, reduce scrap and eliminate re-work.”

Morel Industries will continue to identify, test, and acquire technologies to improve its processes. “We have been in the foundry business for over three generations and we have perfected the craftsmanship, it is now up to my generation to take this old-world craftsmanship and integrate it with the latest in technological advancements in manufacturing.” explains, Morel. Morel, would not tell us what his next acquisitions will be, but he did say their acquisition plan will solidify their company as having the fastest prototyping and manufacturing turnaround times in the industry. Morel ends with “Offering the highest quality craftsmanship, with the fastest, most accurate, and efficient manufacturing processes is a winning equation”. It is hard to disagree. We will continue to keep a close eye on Morel Industries as they execute their strategic innovation plan.

The Story Behind the Medallion

Morel Industries is proud and grateful to be featured in Emerald City Search's "The Story Behind the Medallion" by Clue Meister. "So, our quest was to find a local foundry that could actually work with ZAMAK to produce a Medallion for us. After a couple of dead-ends we discovered the folks at Morel Industries. As their web banner says, they have been around since the 1890s, so it was clear from the get-go that they were steeped in Seattle’s history. What we didn’t know is what we would find when we met owners Mark and Steve Morel. First of all, they are very friendly and approachable, and it was clear they were passionate about what they do. You get a real “down to earth” feeling while talking with them that is quite unexpected when you consider the massive industrial space they work in, full of smells and sounds of metal being poured, formed, ground, and polished into almost any imaginable shape or size."

Read the rest of the article at the link below!

http://emeraldcitysearch.org/log/2012/05/15/the-story-behind-the-medallion/

Morel Industries Casts Art Project for Seattle's International Children's Park

Morel Industries was recently contracted to help develop a public arts project for Seattle's International Children's Park. Artist, Stuart S. Nakamura, developed and installed the art. He describes the artwork as, "Inspired by the universal presence of certain toys shared by Pacific Rim cultures, I have selected sculptural interpretations of tops, rolling hoops, and a woven rattan game ball to supplement the overall vision of the park’s layout and playscape features."

Morel Industries Launches our New Site

Morel Industries are proud to announce we have launched our new website www.MorelIndustries.com. We worked with Harley Lever of WeSprout Solutions to make our site more user-friendly as well as incorporate the latest in website technologies. This is the first step in what we know will become an increasingly more powerful marketing and business development system.

We can now also be found on Facebook and Twitter. We will update these sites with new products, new services, and industry-related news. PLEASE FOLLOW US!!!

If there is any information or features you would like to see on our new site to help make your experience better, please do not hesitate to let us know!