Specialists in all types of aluminum castings, brass-bronze castings and gray iron alloys. A leading Seattle foundry - Morel Industries - offering the very latest techniques in casting high quality products to industry. Also marine cast products from the smallest boating items through to large industrial clients including shipbuilding companies and the United States Navy.

HISTORY:

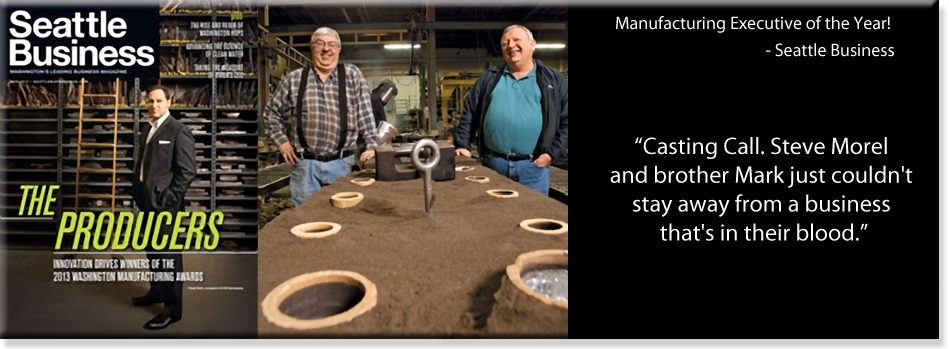

Morel Industries, Inc. was purchased by Stephen and Mark Morel in October of 2000, from the Rowe family. The Company was then known as Ballard Brass & Aluminum. In 2008 the Company was re-named Morel Industries after its relocation from the Ballard area to the new facility inSouth Seattle. But it didn’t start there.

Background:

The Morels have been in the foundry industry for four generations. It all started in Paris with their great grandfather, and their grandfather Leon Morel, Sr. In the late 1800s Leon Sr. was an indentured servant in the Rudier Foundry in Paris, France, where most all of the Rodin bronzes were poured. This is where he learned his skill as a foundryman and artist.

After eight years of servitude he took his consummate skill and immigrated to the United States. In the early 1900s, Leon Sr. worked for two foundries in Seattle; Cascade and NePage-McKinney. Cascade Foundry poured artistic castings and NePage-McKinney produced light standards for the electrification of cities on the West coast. By 1917, Leon Sr. owned both foundries and renamed them Morel Foundry.

The company was passed on to Leon Jr., the only son of Leon Sr., in 1960. In this post-WWII period the foundry grew and began focusing more on aluminum castings. By 1970, Morel Foundry was pouring only aluminum and was considered one of the premier casting sources for companies such as PACCAR (Kenworth and Peterbilt Trucks), FMC/United Defense (military vehicles), Caterpillar (tractors), Boeing Commercial Airplane Company, Garret/AirResearch, John Deere Engine Works, John Deere Product Engineering, Freightliner Trucks, as well as many local companies in the greater Seattle and Pacific Northwest region.

In 1989 Stephen and Mark took over Morel Foundry from their father Leon Jr. Sales at that time were around $7 million/year. They began expanding the customer base and within a couple of years had grown the sales to $9 million. In 1993 the Port of Seattle, thru the right of eminent domain, condemned the land surrounding Morel and 11 other businesses in theWest Seattle tide flats.

After putting together a deal with the Port of Seattle that allowed the company to relocate, a new facility was established in Entiat,WA. Prior to the move, Morel only made patterns and castings, and heat treated them in-house. After the move to Entiat the company added machining, powder coating and assembly. By mid 1997, sales were at a $15 million run rate.

During this growth period, Morel was approached by several companies wishing to merge. The appeal was both the customer base and the state of the art shop. In December 1995, Morel merged with Pacific Aerospace & Electronics out of Wenatchee,WA. Both Stephen and Mark stayed with the new company until August 1997.

In January 1998, Stephen moved back to Seattle and was hired by Vern Rowe as General Manager of Ballard Brass. In 1999, Mark followed Stephen back to Seattle and was hired by Thomas Machine & Foundry to manage their relocation from Mukilteo, WA, to Marysville,WA.

In April 2000, Stephen and Mark began talking with Vern Rowe about buying Ballard Brass & Aluminum. The deal was finalized in October 2000.

In 2006 it was decided to re-locate Ballard Brass & Aluminum from the 11,000 sq. ft. facility in Ballard. The company was spending hours a day moving parts in and out of the facility and on to the city streets. February of 2008 a deal was struck for a building in the Georgetown area that was 42,500 sq. feet. The no-bake molding line was more than doubled in size. The cleaning & finishing room was nearly tripled in size as well to prepare for the addition of an automatic molding machine. In August of that year the move was complete and the name changed back to Morel Industries.