PROCESSES

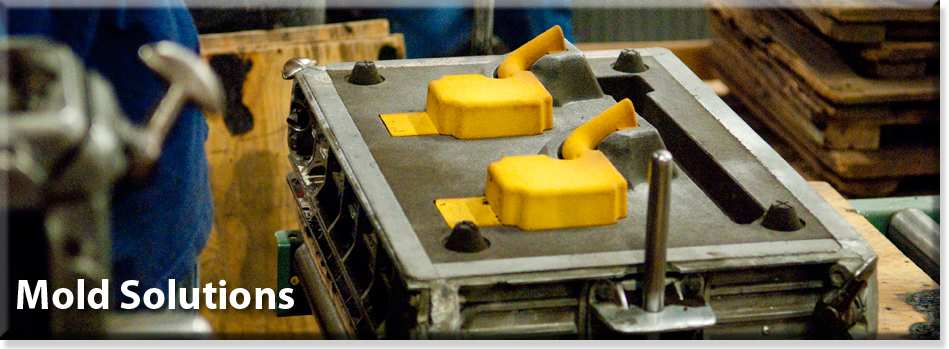

At Morel Industries, we use three types of Molding Processes to manufacture our quality castings: Green Sand Mold, No Bake Mold, Semi Permanent Mold. The casting process is fundamentally a process in which we produce a replica pattern of the finished article. Patterns are usually made of aluminum or other metals, although wood and plastic pieces are sometimes used to provide intricately shaped detail. The finished patterns are used to make molds which are then filled with molten metal to make the finished casting.

The most widely used form of molding is sand molding, because of sand's ability to form and hold detail, and because the sand can be reclaimed and reused over and over.

Factors such as casting size, shape, complexity, quantity, surface finish and dimensional accuracy must all be taken into account when selecting the most cost-effective process for the job. Certain processes may cost a little more, but their greater precision may result in less finishing or machining operations at the back end which will reduce the cost and thus make it more cost-effective to the customer.

We will always find the most suitable and cost-effective method to produce your castings whether it be for individual light castings or multiple heavy castings.

Click on any of the three processes above to learn more about them.