NO-BAKE SAND MOLDS

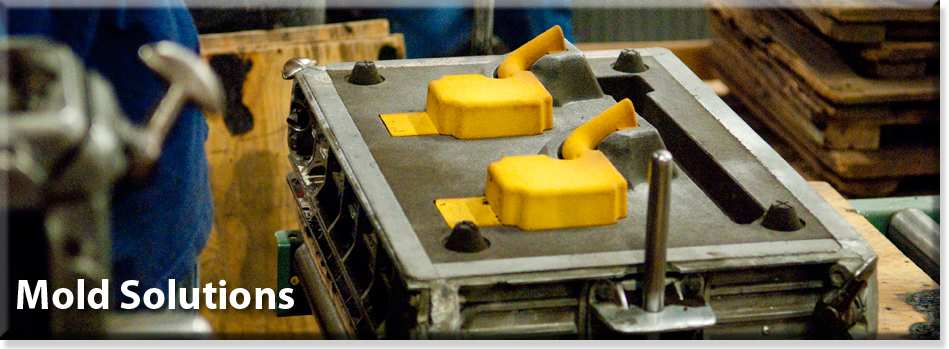

The No-Bake Sand Casting process consists of sand molds created using a wood, metal or plastic pattern. Sand is mixed with a urethane binder and deposited into a box containing the pattern (and all necessary formers and inserts) for pouring. The sand mixture sets hard in a short time, and the mold is then removed from the pattern. Cores for forming internal passages in the castings are made using the same process.

The No-Bake casting technique creates molds with excellent dimensional stability. The casting surface finish is also improved over other sand casting processes.

No-Bake is one of the most efficient and advanced sand casting techniques currently available.

At Morel Industries we use No-Bake Molding for high precision castings in Brass/Bronze and Aluminum and Iron alloys.

No Bake sand casting process used in alloy castings

below left - Filling a wood mold with sand

below right - Pouring molten metal into closed molds

|

|

|

Filling a wood mold with sand |

Pouring molten metal into closed molds |